Formply

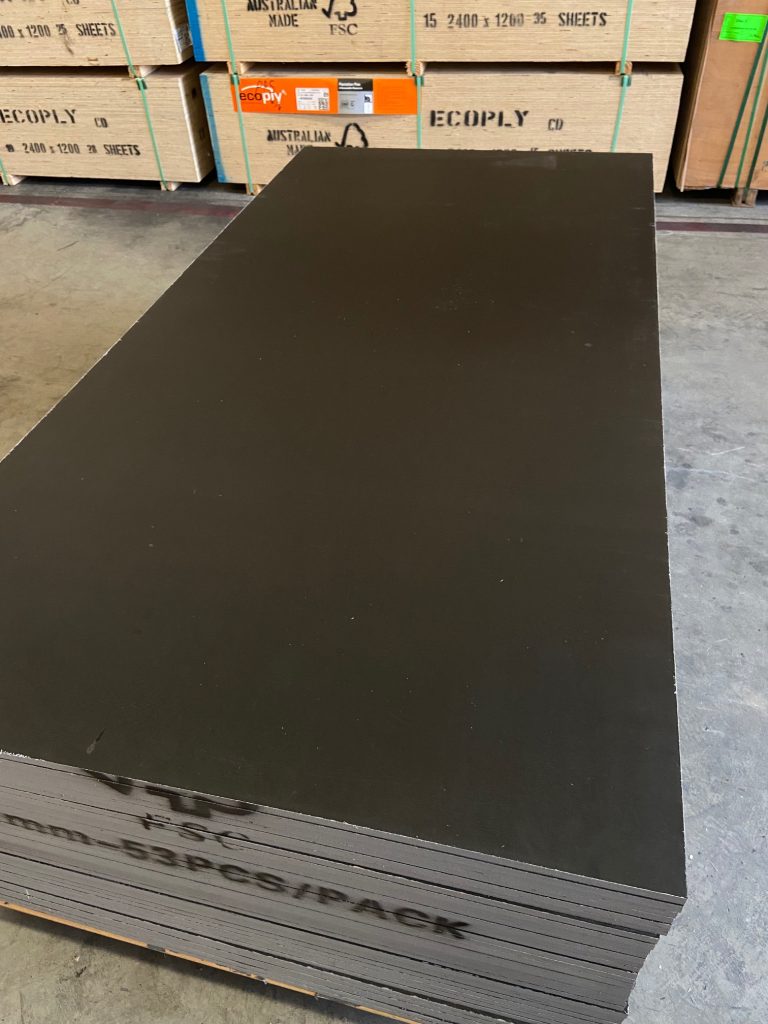

Structural Formply

With its durable, smooth and hard-wearing resin impregnated surface and acrylic painted edges, this is an effective solution when used in conjunction with good formwork practices to withstand the rigours of the harsh construction environment. Structural F17 in the below thicknesses:

Sheet Details (Click to Expand)

| Length x Width (mm) | Thickness (mm) | Sheet Weight (Kg's) | Image |

| Specification Sheet Structural Formply | |||

| 1800 x 1200 | 17 | 22.0 |  |

| 2400 x 1200 | 12 | 20.7 | |

| 2400 x 1200 | 17 | 29.4 | |

| 2400 x 1200 | 25 | 43.2 |

For more information on Plywood Specifications

Non-Structural Formply

A hardwood plywood that has a hard-wearing resin impregnated overlay, with a smooth surface both sides & acrylic painted edges. It’s fit for use in applications that require a durable finish and moisture resistance subject to limited exposure. Non-structural products must not be used in any structural or load-bearing applications.

Sheet Details (Click to Expand)

| Length x Width (mm) | Thickness (mm) | Sheet Weight (Kg's) | Image |

| Specification Sheet Non-Structural Formply | |||

| 2400 x 1200 | 12 | 21.8 |  |

| 2400 x 1200 | 18 | 32.7 | |

| 2400 x 1200 | 25 | 45.4 |

For more information on Plywood Specifications

Non-Structural Formply Grip Deck (Non-slip)

A hardwood plywood that has a hard-wearing resin impregnated overlay, with an embossed slip-resistant on one side and a smooth surface on the other & acrylic painted edges. It’s fit for use in applications that require a durable finish and moisture resistance subject to limited exposure. Non-structural products must not be used in any structural or load-bearing applications.

Sheet Details (Click to Expand)

| Length x Width (mm) | Thickness (mm) | Sheet Weight (Kg's) | Image |

| Specification Sheet Non-Structural Grip Deck | |||

| 2400 x 1200 | 12 | 21.8 |  |

| 2400 x 1200 | 18 | 32.7 |

For more information on Plywood Specifications

FAQ

What is formply?

Formply is plywood with a high-density phenolic resin impregnated paper with sealed edges.

Can formply be used outside?

Yes, we recommend the Structural Formply with its marine glue line. On the other hand, the Non-Structural is better suited for semi exposed applications or temporary exposed applications.

Please ensure that any cut edges are resealed to ensure against moisture ingress leading to rot & decay. Ideally for any holes to be predrilled & spray paint applied to seal the hole prior to affixing the panel.

What’s the difference between Structural & Non-Structural?

- Structural has been put through testing and has a higher breaking strength.

- Structural has an A-Bond Marine glue line compared to the Non-Structural which has a B-Bond exterior glue only suitable for semi-exposed or temporary exterior applications.

Can formply be painted?

The only product reported to have worked on the phenolic face with our customers is B-I-N Primer Sealer by Zinsser.

Technical Information

| Formply | |

|---|---|

| Plywood Technical Information | Specifications |

| Structural Plywood - Design Guide | Engineered Wood Products Association of Australasia |

| Fire Resistance | Engineered Wood Products Association of Australasia |